Electrical Wiring GFCI Outlet Step-by-Step Guide For Real Homes With 2026 Code Talk

Every year, people get shocked in bathrooms, kitchens, and back patios, but a GFCI cuts that power in a split second, and wiring one is way easier than you think. A regular outlet keeps feeding power even as your body becomes the path to ground, and a properly wired GFCI outlet senses that and cuts it off fast.

Shocks around sinks, garages, and pool decks happen way more than homeowners realize. Follow this step-by-step guide, and you can wire a GFCI safely yourself and match the 2026 NEC rules while you’re at it.

If you can turn a breaker off, strip a wire, and tighten a screw, you can handle electrical wiring and GFCI outlet work, and make the riskiest spots in your house much safer.

Maybe that old bathroom outlet near the sink. Looks yellow, loose, kinda sad. Or the garage outlets that trip whenever you run the shop vac and the miter saw in Texas heat. Or the outdoor outlets by the hot tub that some flipper slapped in during a rush job.

You read about people getting nailed in bathrooms or near pools. That part is real. Hundreds of shocks every year in wet areas. A regular outlet just sits there and keeps feeding power while your body becomes the path. A GFCI, a ground fault circuit interrupter, kills it in a tiny slice of a second. That fast reaction is the difference between a scare and an ambulance.

If you searched electrical wiring gfci outlet because you want to do it yourself and not burn the place down, you’re my kind of cautious. Nervous is fine. Cocky is the problem.

Straight talk. I’m not on your job. I can’t see your panel or that outlet box in the wall. If it’s complicated or you’re unsure, hire a pro. Off. Turn it off. Call someone who does this every day. No shame.

In this guide, I’ll walk you through what a GFCI receptacle really does, how line terminals and load terminals work, which wire goes where, and how to wire a GFCI outlet both as a stand‑alone and when you want downstream protection on other outlets. We’ll hit tools, safety moves, the National Electrical Code stuff for bathrooms, kitchen outlets, outdoor outlets, garage outlets, the 2026 talk on HVAC GFCIs, the whole deal.

By the end, you’ll know how to handle a basic electrical wiring GFCI outlet project safely, and when to back away and let someone like me earn their money.

What Is a GFCI Outlet and Why Do You Need One?

Let’s strip the mystery off this thing.

GFCI means ground fault circuit interrupter. Long name, simple idea. It monitors the current flowing out on the hot wire and back into the neutral wire. Black wire out, white wire back. Those numbers should match.

If even a tiny amount starts leaking somewhere else, like through your wet hand to a stainless sink, the GFCI sees that imbalance and slams off fast. We’re talking fractions of a second. That is real-life electrical shock prevention, not marketing fluff.

Regular outlets don’t care about you. They just deliver whatever the breaker allows. That breaker only trips on big overloads or short circuits. So yeah, regular outlets keep feeding power even if you’re the ground path. GFCI doesn’t.

You’ll see a couple flavors

Tamper-resistant GFCI. Has little shutters in the slots. Kids can’t shove forks into one side. You need a real plug that hits both slots to open it. I wire these everywhere kids might be.

Weather-resistant WR GFCI. For outside. The plastic holds up better in sun and rain. The guts are sealed better. In California, with smoke and dust from wildfires settling on everything, WR is required for outdoor outlets. In Texas, cheap indoor GFCIs on patios just cook and die in two summers. WR survives.

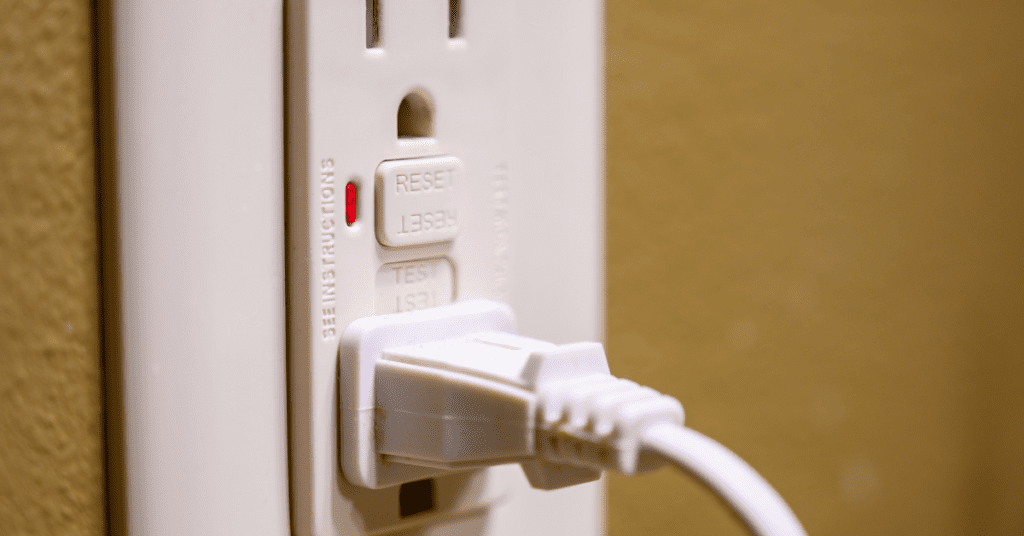

All of them have test and reset buttons on the front. Hit test, it should trip and shut off. Hit reset, it should click and power returns. That’s how you know the ground-fault protection is active.

If you want bathroom outlets, kitchen outlets, laundry, or that sketchy basement corner to be less of a lottery, you use GFCIs. National Electrical Code keeps adding more spots every cycle. Because they work.

Tools and Materials You’ll Need

You don’t need a whole electrician’s van for a basic electrical wiring gfci outlet job. But you do need a few honest tools that won’t lie to you.

Stuff I’d have on the counter

- Voltage tester.

A real one. Klein, Fluke, Southwire. Non‑contact is fine for yes or no power. A meter is better if you know how to read it. Don’t buy dollar store testers. They lie. I’ve seen them show dead when the cable was live. - Wire strippers.

Proper notch for 14 and 12 gauge, since most house circuits are 15-amp or 20-amp. Clean strip, no nicked copper. - Screwdrivers.

Decent Phillips and flat. Long enough to reach into a crowded outlet box. - Needle nose pliers.

For bending hooks on conductors, pulling Romex through the box, and straightening old wires. - Wire nuts.

Real ones, sized for the number of conductors you’re tying. Ideal, 3M, that type. Not the mystery caps that came in some random kit. - Electrical tape.

For wrapping around the GFCI body once the terminals are tight. Gives you a little extra separation inside metal boxes. Not for fixing bad splices. - UL listed GFCI receptacle.

Match the circuit. If it’s a 15-amp circuit on 14 AWG NM cable, get a 15‑amp device. If it’s a 20-amp circuit on 12 AWG Romex, get the proper rated GFCI that can handle a 20‑amp feed. Make sure you see UL listed on the back.

If you’re adding a new outlet location, not just swapping, you may also need a short run of NM cable, usually called Romex, plus an old work outlet box rated for the wall type. Same gauge as existing circuit, no cheating down.

That’s it. No need for a fancy wiring diagram app. Just honest tools, decent materials, and some patience.

Electrical Wiring GFCI Outlet

Important Safety Precautions Before You Start

I know you want to jump in. Slow down a second. This is where we keep you out of the ER.

- Turn the circuit breaker off.

Go to the panel. Flip the breaker you think feeds that outlet. - Test that it’s really dead.

Use your voltage tester on the receptacle slots. Then pull the cover plate and test the actual wires. Hot to neutral. Hot to ground. Nothing should light up. Test everything twice. I got zapped once being lazy in an old Midwest farmhouse and I still remember the taste of it. - No live work.

You are not proving anything by working hot. You slip, your hand hits a grounded metal box and the hot wire at the same time, your heart gets a nasty surprise. Seriously, don’t fry yourself for a ten dollar part. - Wear safety glasses.

Little bits of drywall, rust, ancient spider junk, it all falls when you open boxes in garages and basements. Eyes are hard to fix. - Watch for aluminum wiring.

If the conductors look dull gray, not like normal copper, stop. Old aluminum branch circuits need special CO/ALR rated stuff, anti‑oxidant, and torque specs. Aluminum wiring compatibility is its own topic. Call a pro who knows that world. Don’t learn it on YouTube while your panel is open. - Avoid wet floors.

Don’t stand in a puddle on a concrete garage floor while you mess with outlets. Dry shoes. Dry hands. Seems obvious but I’ve watched people do the opposite. - Stay in the simple DIY lane.

One GFCI swap. Maybe a couple of bathroom outlets tied together. Straightforward garage outlets. Good. If you open the box and see five NM cables, weird splices, a 3‑way switch in the same box, and you feel confusion start climbing, that’s your sign to stop.

Do those and any electrical wiring gfci outlet job you tackle will be way safer already.

Understanding Line vs Load Terminals on a GFCI

This part matters. A lot of DIY GFCI installs fail right here.

On the back of a GFCI receptacle, you’ll see two groups of screws. One marked LINE. One marked LOAD. The marking might be tiny, so you actually have to look. Don’t guess.

LINE is the incoming power from your panel. That’s the feed. That pair of line terminals is what wakes the GFCI. Hot wire, usually the black wire, goes on the brass screw on the LINE side. Neutral wire, the white wire, goes on the silver screw on the LINE side.

LOAD is for protecting downstream outlets. Power leaves the GFCI through those load terminals to other receptacles. Anything fed from those load screws gets downstream protection. Same deal. Hot on brass. Neutral on silver.

Then you’ve got the green ground screw on the metal strap. That’s for the ground wire, usually bare copper in modern NM cable or green if someone added a pigtail. That ground ties every metal part together so faults clear fast.

If you only want that single GFCI to protect itself, you don’t use the load terminals at all. Leave them empty. Most devices ship with tape over them. That’s a good clue. Tape can stay if you’re not protecting downstream outlets.

If you want one GFCI to protect a string, like multiple bathroom outlets or several garage outlets, you hook the outgoing black and white onto the brass and silver load terminals. That’s how you get downstream protection.

Mix them up and bad things happen. Sometimes the device won’t reset at all. Sometimes it seems to work, but the ground-fault circuit interrupter doesn’t actually protect anything. Last summer a guy near Sacramento nearly drowned in his hot tub from a reversed line and load. The GFCI looked fine. Lights on. Outlet powered. But it never correctly identified the fault. Still gives me chills.

So yeah. LINE gets power from the panel. LOAD protects the rest of the chain. If you’re not sure which cable is which, you slow down, test, and figure it out. Or you stop and call someone.

How to Wire a GFCI Outlet (No Downstream)

This is the simple version. One cable in the box. Or you choose to only protect this one receptacle and nothing downstream. Good starter electrical wiring project: gfci outlet.

- Turn the circuit breaker off.

Back to the panel. Flip the breaker. Don’t trust the wall switch. - Confirm it’s dead.

Tester in the outlet slots. Nothing. Pull the cover plate. Gently pull the old receptacle out of the outlet box. Test the bare terminals. No reading from hot to neutral or hot to ground. Then you can breathe a little. - Study the existing wiring.

For the simple setup you’ll see one NM cable with a black wire, a white wire, and a bare copper ground wire. If you see more than one cable, you can still do stand‑alone; you just cap off any pass‑through and leave load empty. - Remove the old outlet.

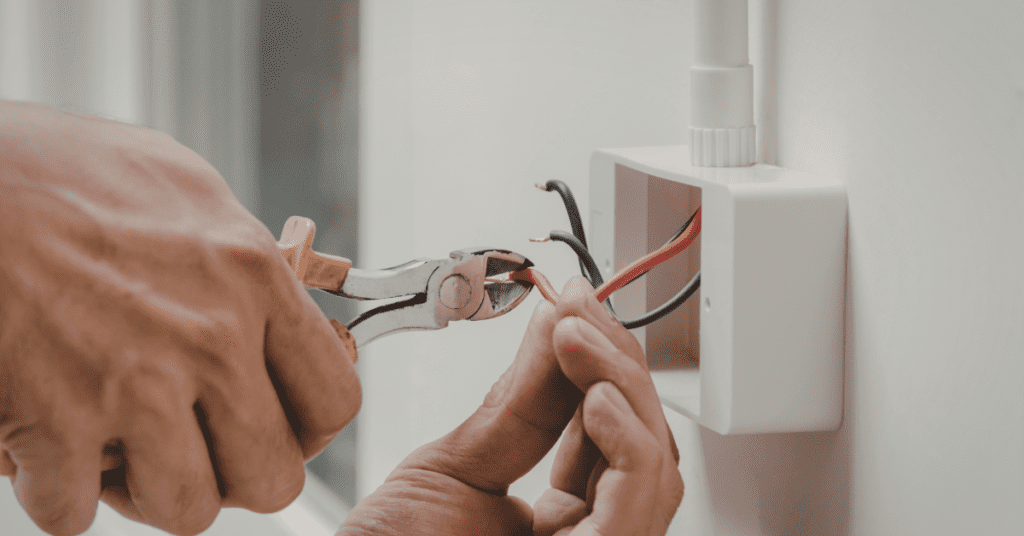

Loosen the side screws. If the conductors are under backstab holes, release them and cut back to clean copper. Straighten the ends with needle-nose pliers so you’ve got nice straight conductors to work with. - Strip and prep the wires.

About half an inch of insulation off the black and white if needed. Not a full inch. Not a tiny sliver. Use wire strippers, not your teeth. Bend small hooks on the black and white, turned so they wrap clockwise under the screw heads. - Land the ground wire first.

Take the bare copper. If you have a metal box, tie it and any other grounds together with a wirenut and a short pigtail, then put that pigtail on the green ground screw of the GFCI. Tight, but not so tight that you twist the wire off. Ground gives a fault a safe path. - Hook up the line hot and neutral.

Find the side marked LINE on the GFCI. That’s the only one you’re using for this. Black wire goes under the brass screw on the LINE side. The white wire goes under the silver screw on the LINE side. Tighten the screws so the wire doesn’t wiggle. Black to brass LINE, white to silver LINE. If your device has clamp style backwire terminals, slide the stripped end straight in, then tighten the screw that clamps the plate down. - Ignore the load terminals.

If there’s tape over the load screws, leave it. If not, fine, just don’t hook anything there. You’re not protecting downstream outlets in this step. That keeps it simple. - Tuck everything back in the box.

Fold the wires in a gentle zigzag. Don’t mash them into a ball. Keep the bare copper ground away from the brass and silver terminals. This is where I like a wrap of electrical tape over the sides of the GFCI before I push it in. Small buffer between live screws and the metal box. - Mount and test.

Screw the GFCI into the outlet box. Install the cover plate. Turn the breaker back on. Press RESET on the GFCI. Plug in a lamp. Hit TEST. Lamp should go out. Hit RESET again and the lamp should come back. If the test and reset buttons act weird, or it won’t reset at all, stop and recheck your wiring before you use it.

That’s the clean single device method. One electrical wiring gfci outlet job done right, no drama.

How to Wire a GFCI to Protect Downstream Outlets (Using Load Terminals)

Now the slightly trickier version. Same GFCI receptacle, but this time we want it protecting downstream outlets too. Bathroom circuits, garage outlets, laundry nook, that type of run.

You open the box and see two or three NM cables. That usually means one feed from the panel and one or more cables going out to other outlets. Those other ones are what you’ll be protecting downstream.

You have to figure out which cable is feed. Sometimes you can guess by layout, but I like proof.

Quick method I use in simple cases

Breaker on. Carefully separate the black wires so they’re not touching anything, cap each one alone with a wirenut, and use a voltage tester to see which black wire is hot. That’s your incoming feed. Mark that cable with a bit of tape. Breaker off again before you touch anything else. No live work beyond testing.

Once you know which is feed and which go out, wiring goes like this.

- Tie all grounds together.

All bare copper or green grounds get twisted together with a wirenut. Add a short ground pigtail if needed. That pigtail lands on the green ground screw of the GFCI. If the box is metal, another pigtail from that bundle goes to a ground screw in the box. Everything grounded, everything bonded. - Connect the feed to LINE.

Feed black wire to brass LINE screw. Feed white wire to silver LINE screw. Those are the line terminals that power the GFCI. That’s it for the feed pair. - Build pigtail wires for the load side.

Say you have two cables heading out to other outlets. Take both outgoing black wires plus a short black pigtail wire, same gauge, and tie those three together with a wirenut. Do the same for the white wires with a white pigtail. These pigtail wires are what will land on the load terminals. I’ve seen flipped houses in suburbs where they skipped pigtails and jammed three wires under one screw and yeah, they paid for it later. Loose, burnt, dead half circuits. - Connect the load terminals.

Black pigtail to brass LOAD screw. White pigtail to silver LOAD screw. Now when the GFCI trips on a ground fault, it kills power to every outlet fed from those outgoing cables. That is downstream protection in action. - Double check everything.

Feed cable only on LINE. All the “going out” stuff only tied into LOAD through pigtails. Grounds solid. No bare copper touching something it shouldn’t. If the box feels crowded, that’s normal, just don’t cram so hard you crack insulation. - Close it up and test the string.

Mount the GFCI and cover plate. Breaker on. Hit RESET. Plug a lamp into the GFCI outlet and one into a downstream outlet. Hit TEST on the GFCI. Both lamps should die. Hit RESET and they both come back. That means you’re protecting downstream outlets correctly.

That’s the classic how to wire a GFCI outlet when you want one device covering a whole section of a bathroom or garage. Electrical Wiring GFCI Outlet Clean, safe, cheaper than buying six GFCIs.

Common Wiring Mistakes and How to Avoid Them (Electrical Wiring GFCI Outlet)

I see the same stuff again and again.

- Reversed line and load.

This is the big one. People hook the feed to the load terminals and the outgoing stuff to line. The GFCI might not reset. Or worse, it sort of works but doesn’t actually trip when there’s a ground fault. Reversed terminals look fine but protect nothing. Always find the real feed before you land wires. - Loose screws and bad wirenuts.

Half tightened brass screw, copper half under the clamp, wirenut twisted on only one turn. Heat cycles and motors starting will make that fail. Tug on every connection you make. It should not pull out. - Forgetting the ground wire.

Bare copper just cut short and left floating in the back of the outlet box. I see that a lot in quick flips. Ground is your friend when something metal goes live by accident. Tie it in. - Wrong device for the circuit.

Shoving a cheap 15‑amp GFCI on a 20‑amp circuit that feeds a kitchen counter and a microwave. Many devices can accept both, but you need to read the labeling. Match your GFCI rating and your 15-amp or 20-amp circuit properly. - Sloppy stripping.

Slice into the copper with dull wire strippers, strip too long so bare metal sticks out past the terminal, then wonder why things arc. Clean cuts, right length, no nicks. - Cranking screws until stuff bends.

Overdoing it with the screwdriver warps the yoke, cracks the outlet box ears, or twists wires right off the terminals. Snug, then just a hair more. Not body builder mode.

If your GFCI won’t reset, first thing I do is kill the breaker, pull it out, and disconnect the load wires. Cap those. Turn power back on. Try again. If it now resets, problem is somewhere downstream. If it still won’t, feed on the line terminals might be wrong or the device itself might be bad.

GFCI Requirements by Location (2026 NEC Updates)

National Electrical Code keeps tightening the rules. Local NEC requirements can be even tougher, so your city might add a twist or two. But here’s the broad picture based on the recent code cycles and where 2026 is heading.

- Bathrooms.

Every receptacle near sinks, showers, tubs. Basically all bathroom outlets. Always GFCI now. No debate. - Kitchen counters.

Any receptacle serving countertop space. Sinks, islands, peninsulas. Install GFCI there and you’ll be in line with inspectors. - Garages.

General use garage outlets, where you plug in tools, chargers, freezers, all that. GFCI across the board on those. - Basements and crawlspaces.

Unfinished basements, damp corners, crawlspaces with receptacles need GFCI protection. Concrete, moisture, metal pipes, that combo is rough without it. - Outdoors.

Exterior receptacles around the house, decks, porches. Use weather-resistant WR rated GFCIs with proper in‑use covers. There’s strong push in the newer codes for outdoor protection up to 60 amps in some situations, so small pool panels and certain outdoor feeds get ground fault protection too. I’ve heard more than one inspector say something close to “NEC 2026 bumped outdoor protection to 60 amps so Texas heat doesn’t kill cheap GFCIs” and honestly, given how regular ones fry in that sun, I get it. - Pools, spas, hot tubs.

Anywhere near water like that, the list of GFCI and bonding rules is long. You get receptacles, lights, pumps, all inside specific distances from the water. This is where I often tell homeowners, let a pool electrician handle it. - Laundry.

Laundry area outlets get GFCI now. Washers leak. Hoses burst. Floors get nasty. Code caught up. - HVAC.

Newer NEC versions are rolling in GFCI for certain outdoor HVAC equipment. Expect more talk about special Class C SPGFCI or HF rated gear for condensers after 2026. With all the nuisance tripping problems on early installs, the new devices are smarter about motors.

Self-testing GFCI is quickly becoming standard in many of these spots, especially where the National Electrical Code wants long term reliability. You might not be legally forced to upgrade every old one, but if you’re already opening the box, I like using good self testing GFCIs in rough environments.

Point is, if the outlet is in a place where you could be wet, barefoot, on concrete, or outdoors, code probably wants a GFCI close by now or will soon.

Testing and Maintenance After Installation

You mounted the thing. The light works. You’re not done.

GFCIs wear out. Lightning hits nearby. Surges beat on the internals. Contacts get tired. A ground fault circuit interrupter can quietly fail and still look fine on the wall.

So you test.

Once a month, press the TEST button. You should hear a click and whatever’s plugged in should shut off. Press RESET and power should come back. If it won’t reset, or if pressing TEST does nothing and the outlet keeps working, that device is done. Swap it.

On self-testing GFCIs, watch the little light. If it shows red, or blinking patterns the instructions say are bad, don’t ignore it. The protection might be gone even if the outlet still passes power.

Outdoor outlets and garage outlets live hard lives. Every few years, kill the breaker, pull the cover, and take a quick look. Any melted plastic, brown marks around brass or silver screws, or crispy insulation, I replace the whole thing. Cheap insurance.

Family Handyman types always say “test monthly or it might fail when you need it most” and for once they’re not exaggerating. Takes ten seconds.

Short Circuit vs Ground FaultNFPA 70: National Electrical Code overview.Frequently Asked Questions (FAQ)

How do you do electrical wiring gfci outlet work safely?

Start by killing power at the breaker and proving it with a voltage tester on the receptacle and then on the bare wires in the box. Remove the old outlet, study how many cables you have, and decide if you’re doing a simple line only GFCI or protecting downstream outlets too. Black wire to brass LINE, white wire to silver LINE, ground wire to the green ground screw, all with firm, clean connections. No live work, no guessing which is feed, no half twisted wire nuts. If something looks different than what you expected from any wiring diagram, stop and get help.

What’s the difference between line and load on a GFCI receptacle?

Line terminals are the connection point for incoming power from the panel. That’s what powers the GFCI electronics so the test and reset buttons even do anything. Load terminals send protected power out to other outlets so you get downstream protection. If you use only line, you protect just that one device. If you hook other receptacles to load, you’re protecting downstream outlets too. Mix them up and you can disable the safety function without realizing it.

Which wire goes where on a GFCI?

On a normal branch circuit with modern NM cable you’ve got hot wire in black, neutral wire in white, and bare copper for ground. Black goes to the brass screw on the LINE side for the feed, and to brass LOAD if you’re feeding more receptacles. White goes to the silver screw for line and load the same way. Bare or green bonds to the green ground screw and also to the metal outlet box with a pigtail if the box is metal. Matching colors to terminals keeps things simple and safe.

Do I really need an electrician to install one GFCI?

Not always. A straight swap in a plastic box with one modern copper cable, clear labeling, and a basic 15-amp or 20-amp breaker is well inside what a careful homeowner can do. You follow directions, test twice before touching, and go slow. But if you open it up and find aluminum wiring, scorched insulation, five Romex cables jammed in, or odd stuff like multi wire branch circuits sharing a neutral, that’s when my answer flips to yes, call a licensed electrician. Some jobs are not worth guessing on.

What if there are multiple wires in the outlet box?

That usually means your box is feeding other outlets. One cable is line from the panel, the others go out to other places. You separate them, use your tester with the breaker on briefly to find the true feed, then move everything else to the load side using pigtail wires tied with wire nuts. If that sounds confusing in real life and not just in words, it’s fine to stop, cap the extras safely, and have a pro sort which run is which. Guessing which cable is feed is how people get line and load flipped.

What happens if I mix up line and load?

Sometimes the GFCI just won’t reset, and you stand there jabbing the reset button wondering what you broke. Other times, especially with older styles, it might seem to work as a regular outlet but the ground fault circuit interrupter part won’t trip when there’s a fault. That means no electrical shock prevention at all, which is scary because it looks okay on the wall. If you suspect that, kill the breaker, pull the device, and move the true feed wires to the side marked LINE, then put any downstream conductors on LOAD and test again.

Can I use a GFCI where there’s no ground wire?

Yes, but you have to label it correctly. Old houses sometimes have two wire cable with no equipment ground. You can replace a two prong receptacle with a GFCI and mark it “no equipment ground” and it will still trip on imbalances between hot and neutral. That’s better than nothing. It won’t magically give you a real ground though. Metal cases on tools still won’t have a true equipment ground path. For big upgrades in older homes, running new grounded circuits is usually the safer long game.

Where are GFCI outlets required by code now?

National Electrical Code calls for them on bathroom outlets, kitchen outlets serving counters, garage outlets, unfinished basements, crawlspaces, laundry areas, outdoor outlets, and around pools and similar water spots. Newer cycles add more HVAC and outdoor equipment into the GFCI world too, sometimes with special self-testing GFCIs or breaker style units. Your local inspector might have tweaks, especially in places like coastal areas or wildfire zones in California. If you match what we talked about in the GFCI requirements section, you’re usually close to what your local office wants.

Can I put a GFCI on aluminum wiring?

Not directly unless the device and connectors are made for it. Aluminum wiring compatibility is tricky. You need CO/ALR rated devices, or approved connectors that tie aluminum to short copper pigtail wires, plus anti oxidation compound and proper torque. Slapping a regular GFCI receptacle straight on aluminum branch circuits is asking for loose, hot connections. If you see gray aluminum in that box, that is one of those times I say stop and hire someone who deals with it often.

Do I need tamper-resistant GFCI or self-testing GFCI?

If you have kids or grandkids around, I’d go tamper resistant for sure. Those shutters keep them from poking forks into one slot and getting nailed. Self testing GFCIs are nice because they run a quick internal check on their own, and many will show a light or refuse to reset if the guts fail. For places that are hard to reach or easy to forget, like an outdoor GFCI behind a shrub, I like using a good self testing GFCI that’s UL listed and weather-resistant WR. One less thing for you to baby sit every month.

Conclusion

You don’t have to be an electrician to handle a basic electrical wiring gfci outlet job. You do need to respect what 120 volts can do if you treat it like a toy.

Kill the breaker. Prove it’s dead. Black on brass, white on silver, ground on green. Line terminals for the feed, load terminals only when you’re sure which cables are protecting downstream outlets. Use real parts, real tools, and don’t cheap out on GFCIs just because some mystery brand is five bucks less.

If you hit old wiring, aluminum, crowded boxes, or messy multi room circuits, stop and let a pro untangle it. Same for pools, spas, and new HVAC GFCI rules under the National Electrical Code. Some jobs are perfect DIY. Some are perfect “write a check and sleep well” work.