A Power Transformer is just an electrical transformer built to shove big power around the power grid without turning it into heat and smoke. That’s it. No magic. No “smart” anything. Copper, steel, oil, paper, and a whole lotta ways for humans to screw it up.

You’ll hear folks usually say “it steps voltage up” or “it steps voltage down.” Yeah. A step-up transformer on a generator makes power transmission possible. A step-down transformer at a substation makes power distribution possible. Same animal. Different gym membership.

And don’t let anybody tell you they’re all the same. They aren’t. A 10 MVA unit in a wind farm collector yard ain’t the same world as a 500 MVA bank feeding a metro load pocket where the electrical grid is already one bad day away from the news.

Basic idea:

- Alternating current AC goes into the primary winding.

- A magnetic field builds in the iron core (actually a laminated core, usually silicon steel).

- That changing field couples into the secondary winding.

- You get voltage transformation based on turns ratio.

You think that’s simple? Wait till you’re on hour 19 of an outage with a boss asking why the spare’s BIL doesn’t match and the tap range is wrong and the manufacturer’s tech “can be onsite in three weeks.” Man.

Power transformer life cycle, the ugly version:

- Design. Somebody picks ratings and clearances.

- Factory build. Somebody else tries not to contaminate insulation.

- Shipping. Somebody straps it down like it’s a lawnmower. It isn’t.

- Install. Somebody forgets torque marks on bushings.

- Commissioning. Somebody rushes tests because “we need it hot by Friday.”

- Operation. Magnetizing current and losses hum along forever.

- Maintenance. Either you do it. Or it does you.

- End-of-life. Usually not graceful. Usually at 2 a.m. in weather that hates you.

Reminds me of that mess in ’19 when we got a “new” unit that sat in a yard so long the breather silica gel was pink like cotton candy. Everybody’s acting surprised the oil test came back looking like a gas station slushie.

2. How They Actually Work – Electromagnetic Induction Step-by-Step, Real Math

Alright. Electromagnetic induction. The part everybody nods at like they remember school. Most don’t. That’s fine. I’ll give you what matters.

Step-by-step, no fluff:

- Apply alternating current AC voltage to the primary winding.

- A small magnetizing current flows. Not load current. Just enough to build flux.

- Flux builds in the iron core. Well, “iron.” It’s laminated silicon steel stacked like a book to cut eddy current losses.

- The changing flux creates a voltage in the secondary winding by mutual inductance.

- Connect a load. Secondary current flows.

- That secondary current makes its own flux that bucks the original.

- Primary current increases to keep the net flux about the same. That’s flux linkage doing its thing.

Now the math everybody wants but nobody wants.

Turns ratio:

Transformer Ratio, Current Relation, and Impedance Reflection

Turns ratio (definition):

a = Np / NsVoltage ratio (ideal transformer):

Vp / Vs ≈ Np / Ns = aExample (115 kV to 13.8 kV):

a = 115 / 13.8 ≈ 8.33

Current ratio (ideal transformer):

Ip / Is ≈ Ns / Np = 1 / aImpedance reflection (secondary load referred to primary):

Z′ = a2 ZExample (Z = 0.2 Ω on secondary):

Z′ = 8.332 × 0.2 ≈ 13.9 × 0.2 ≈ 2.78 Ω

That’s why faults look different across sides. That’s why protection settings aren’t “copy paste.” Seen too many relay settings that look like somebody threw darts at a wall.

And please. Please. Don’t drive the core into core saturation. You do that with overvoltage, wrong frequency, or ferro resonance games. Saturation ramps up magnetizing current, distorts waveform, heats the core, trips stuff you didn’t even know was tied to that bus, and then you get to explain to management why the power grid just sneezed.

You think that’s bad? Wait till you see a unit energize into saturation with a stuck tap and the inrush looks like a small war.

3. Power vs Distribution vs Other Types

People mix these up. Then projects get spec’d wrong. Then everyone’s mad. Especially me.

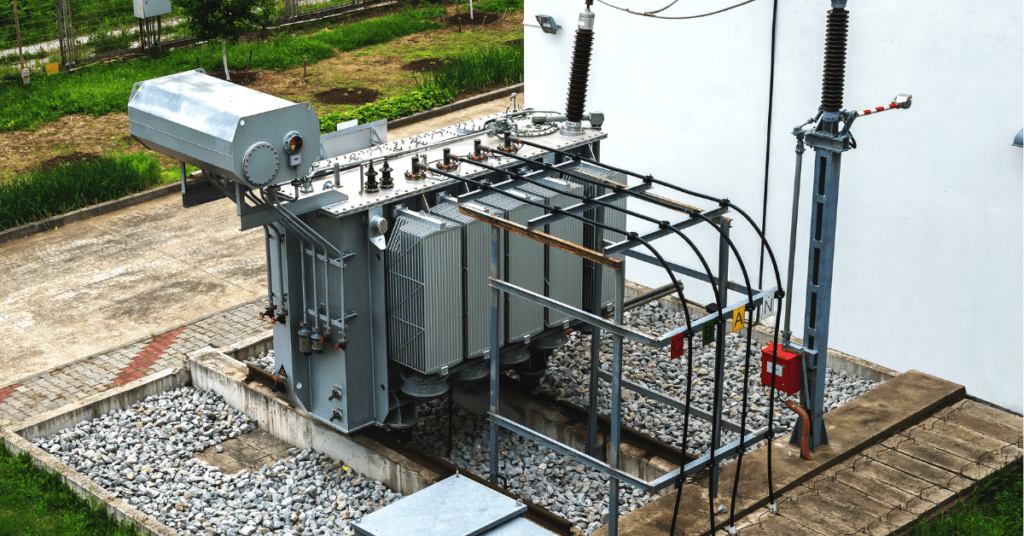

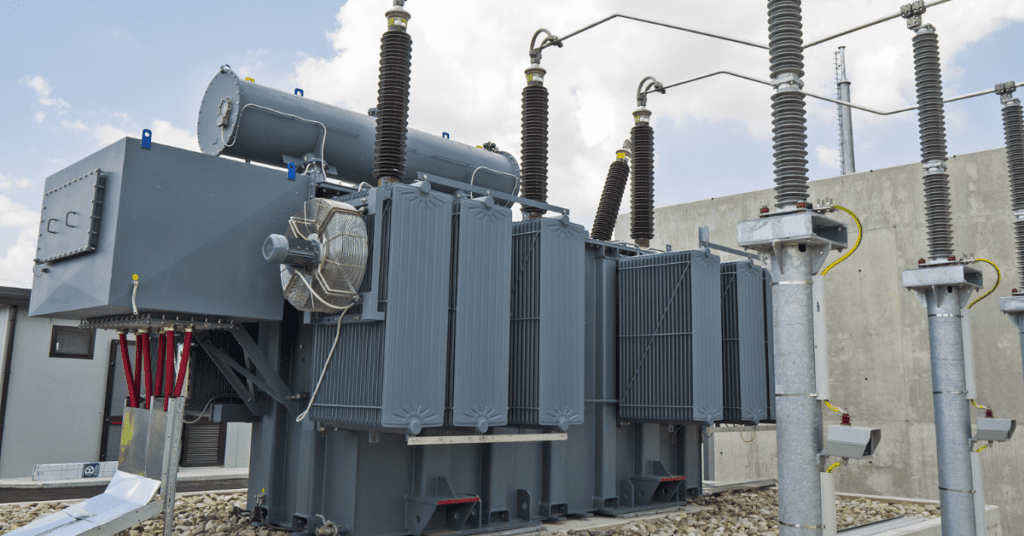

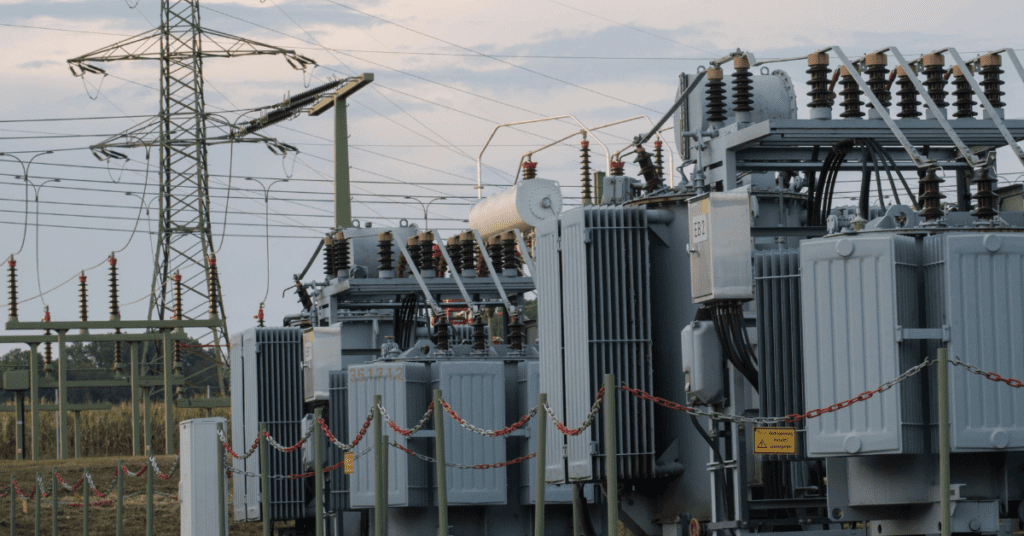

Power transformer (the big boys)

- Used in transmission and big substations

- High kVA MVA rating. Like tens to hundreds of MVA.

- Usually designed for high efficiency at or near full load.

- Often has tap changer OLTC on-load because system voltage isn’t a suggestion, it’s a requirement.

Distribution transformer

- Feeds customers. Lower voltage.

- Designed for good efficiency at partial load, since it sits there all day doing “not much.”

- Smaller ratings. Different thermal assumptions.

- You still screw them up, just cheaper.

Other types you’ll bump into

- GSU generator step-up for renewable energy integration wind solar and conventional plants.

- HVDC converter transformers. Special beasts. Harmonics, DC bias issues, weird stresses.

- Grounding transformers, station service, traction, furnace transformers in industrial plants. Each one’s got its own ways to ruin your weekend.

Big difference in the field? A power transformer failure usually takes friends with it. Breakers, buses, maybe the whole substation if the fire protection’s a joke.

4. Every Damn Type Out There

Yeah there’s “types.” Lots. Vendors love types. Consultants love types even more. Here’s what you actually see.

By insulation/cooling medium:

- Oil-filled mineral oil (most common). Supposedly PCB-free oil unless you’re dealing with ancient stuff.

- Natural ester. Natural ester biodegradable fluids. Better fire point, different moisture behavior, different aging. Not a free lunch.

- Dry-type. Like dry-type cast resin. Indoor, urban substations, commercial buildings, places where oil fire risk makes people twitchy.

By construction:

- Core form vs shell form.

- Three-phase vs single-phase banks.

- Autotransformer vs two-winding. Autos save copper and losses but the fault behavior’s different and you don’t get isolation. Ask me how that goes when someone assumes isolation.

By tap changing:

- Tap changer OLTC on-load. Adjusts under load. Also brings its own maintenance circus.

- Off-load tap changer. You de-energize to change taps. Cheap. Simple. Slow. Always “fine” until it isn’t.

By application:

- HVDC converter transformers

- GSU

- Shunt reactors (not transformers, but they hang out together and confuse new guys)

- Phase-shifting transformers (when you want power flow control and drama)

5. Deep Dive on Components and What Specs Actually Matter

This is where the paper meets the pavement. And the pavement is icy. And you’re carrying a megger case that’s somehow gotten heavier since 2003.

Core

- Iron core is really stacked laminations. Laminated core reduces circulating currents.

- Silicon steel improves magnetic properties, cuts losses.

- Bad core design or assembly can spike hysteresis losses and eddy current losses.

- Core grounding matters. One ground point. Not two. Two grounds makes a circulating loop. Then heat. Then weird gases. Then you’re blaming oil when it’s actually your core.

Windings

- Primary winding and secondary winding copper or aluminum.

- Conductor shape, transposition, bracing, all that decides whether it survives a through-fault.

- Short circuit strength isn’t optional. The grid doesn’t care about your feelings.

Insulation system

This is the soul. Paper, pressboard, oil. Air where it shouldn’t be is death.

Key spec words:

- Insulation class and thermal rating

- Dielectric strength

- BIL Basic Impulse Level. Lightning doesn’t RSVP. BIL is your “take the hit and live” rating.

BIL mismatch is a classic clown show. Somebody swaps a bushing or changes a connection and now your weakest link is the wrong place. Then you get a flashover that looks like a camera flash inside a steel box. Real fun.

Tank, conservator, and the little bits people ignore

- Main tank holds oil and active part.

- Conservator tank on many designs. Oil expands, goes into conservator.

- Breather silica gel dries incoming air. When it’s saturated it goes pink. And then it’s basically decorative.

- Buchholz relay on conservator-type units. It catches gas and sudden oil movement. It’s saved more transformers than any “AI monitoring platform” ever will, honestly.

Bushings

Bushings are the sneaky killers.

- Porcelain. Old school. Fragile. Still everywhere.

- Bushings porcelain RIP. Resin-impregnated paper. Lower maintenance than OIP in some cases. Still test them. Don’t get cocky.

Bushing failures are violent. They don’t “sort of fail.” They go. Then you’ve got oil fire risk, collateral damage, and a report to write while everyone’s staring at you.

Tap changer

- Tap changer OLTC on-load is great. And a pain.

- Contacts wear. Oil carbonizes. Mechanisms stick.

- If your OLTC compartment is nasty, that nastiness doesn’t stay politely in its box forever. It migrates. It contaminates. Then you’re chasing partial discharge PD ghosts.

Nameplate stuff that actually matters

- kVA MVA rating at certain cooling stages (ONAN, ONAF, etc.)

- Impedance %. Impacts fault current and voltage regulation.

- BIL. Already said it. I’m saying it again because people ignore it.

- Sound/noise rating. Noise level regulations are real. Neighbors complain. Then you’re building a wall that makes cooling worse. Great plan.

6. Losses – Where Your Money Burns Up, Efficiency Reality

Losses are where you pay forever. Capex hurts once. Losses hurt every hour until retirement or until the unit dies, whichever comes first.

Two big buckets:

No-load losses (core losses)

- Mostly hysteresis losses and eddy current losses

- Happens anytime it’s energized, load or no load

- Driven by voltage and frequency and core material

- If you’ve got a unit sitting hot, lightly loaded, that no-load loss is still cooking away. Like leaving a space heater on because you like the hum.

Load losses (copper + stray)

- I²R in windings

- Stray losses in tank, clamps, leads

- Scale with load squared. Double load, four times heating.

Now let’s talk energy efficiency standards DOE regulations 2016 202X. I’ve watched these rule changes come through like weather. Some are fine. Some are paperwork. Some push designs thinner on margin. You want lower losses? Cool. You’ll pay for more copper, more core steel, bigger footprint, maybe more weight. Then shipping costs go up. Then foundations change. Then the schedule slips. Then the same people who demanded “high efficiency” scream about the budget.

Honestly it’s a joke sometimes. Not the physics. The way it’s sold.

And don’t forget losses turn into heat. Heat kills insulation. That’s not poetry. That’s chemistry.

7. Cooling Systems – Heat Kills Faster Than Faults

I’ve seen more transformers cooked to death than “mysteriously failed.” Heat, moisture, oxygen. The slow killers.

Cooling types show up on nameplates like alphabet soup. Here’s a quick table that won’t lie to you.

| ONAN | Oil Natural Air Natural | Natural convection oil, radiators, no fans | Dirty radiators, blocked airflow, bad gauges |

| ONAF | Oil Natural Air Forced | Fans add air cooling | Fans fail, controls fail, people disable alarms |

| OFAF | Oil Forced Air Forced | Oil pumps + fans | Pump seal leaks, flow switches lie, maintenance gets skipped |

| Dry-type | Air cooled | No oil | Dust, hot spots, crappy ventilation, PD if abused |

| Cast resin | dry-type cast resin | Resin insulation, decent in buildings | Cracks, thermal cycling, harmonics heating |

You want a field truth? Fans don’t fail when it’s 65 and sunny. They fail during a heat wave when your load is pegged and you’re already sweating through your shirt.

And oil pumps. Man. Oil pumps love to fail quietly. A stuck flow switch. A miswired alarm. A pump running backwards after a motor swap. I’ve seen it. Don’t laugh. Some poor tech wired phases wrong and nobody checked rotation. Transformer ran hotter than it should. DGA started screaming. Everybody ignored it. Then we got the call.

Cooling ties right into grid reliability resilience. You lose one big transformer in a constrained pocket, you’re not just swapping a part. You’re reconfiguring the power grid with duct tape and prayers.

8. Maintenance – What Keeps These Alive or Kills Them Quick

Maintenance is boring. Until it’s not. Then it’s the most expensive thing you didn’t do.

You want the short list? Fine.

Preventive maintenance that actually matters

- Visual inspections. Leaks, hot spots, weird sounds. Yeah, listen to it. A transformer tells on itself.

- Oil sampling. Properly. Not outta the bottom drain with a dirty hose.

- Check breathers. Breather silica gel condition.

- Check Buchholz relay operation and gas collection if applicable.

- Cooling system checks. Fans, pumps, controls.

- Bushing checks. Power factor/tan delta, capacitance trend, IR scans.

Oil testing, the big one

Oil is your bloodwork. Ignore it and you’re guessing.

Core tests:

- oil testing DGA Dissolved Gas Analysis acetylene hydrogen methane ethylene

- Moisture (ppm)

- Dielectric breakdown

- Acidity (neutralization number)

- Interfacial tension

- Inhibitor content

- Particle count sometimes

DGA basics, the “stop pretending” edition:

- Hydrogen: partial discharge, corona, arcing sometimes

- Methane and ethylene: thermal faults, oil overheating

- Acetylene: arcing. Real arcing. “Oh it’s a little acetylene” is like saying “it’s a little pregnant.”

I once watched a 230/115 kV unit ramp acetylene over a couple weeks. Emails flew. Meetings happened. Nothing got done because nobody wanted the outage. Then it arced hard. Dumped gas. Buchholz tripped. Lights flickered. And management looked shocked. Like the DGA was just a suggestion box.

Oil filtration, reclamation, and the stuff people confuse

- oil filtration reclamation aren’t the same.

- Filtration removes water and particles. Reclamation can remove acids and sludge, restore oil properties with fuller’s earth or similar process.

- Reclamation can buy time. Not immortality. Your paper insulation still ages.

Insulation aging

Heat and moisture reduce degree of polymerization. The paper gets brittle. Then a fault that used to be “survivable” becomes a winding collapse.

You want a rough rule? Every 6 to 8°C hotter than design, insulation life drops hard. Depends on model. Depends on moisture. But the trend’s real. Don’t run it hot just because you can.

Overhaul

Overhaul isn’t “let’s open it up for fun.”

- You do it for OLTC issues, leaks, bushing swaps, internal inspection after a fault, major oil contamination.

- You better have a plan for contamination control. Oil processing, dry air, vacuum, clean tools.

- One greasy rag in the wrong place. Then you’ve planted a failure you won’t see for 3 years.

9. Testing Full Spectrum – Factory to Field Nightmares

Testing’s where you find out if the thing is real or just looks real.

And yeah. Testing’s where schedules go to die.

Factory tests (typical)

- Ratio, polarity, vector group

- Winding resistance

- No-load loss, load loss, impedance

- Applied voltage, induced voltage

- Partial discharge sometimes

- Temperature rise test for certain units

Field commissioning tests (the ones you should actually do)

I’m gonna list them and I’m gonna tell you what they catch.

- insulation resistance megger

Catches gross insulation problems, moisture, contamination. Trend it. Don’t just accept one number. - turns ratio test TTR

Catches wrong tap position, wrong internal connections, shipping damage sometimes. Energize without checking ratio? Seen units blow sky-high. Not kidding. - winding resistance

Catches loose connections, bad tap changer contacts, winding issues. Compare phases. Compare taps. Look for weird jumps. - SFRA sweep frequency response analysis

SFRA sweep frequency response analysis is the “did the winding move” detector. Shipping can shift clamping. Faults can deform windings. SFRA sees that when DCR doesn’t. - partial discharge PD

Useful. Touchy. Needs good setup. Good noise rejection. If you don’t know what you’re doing you’ll chase ghosts and still miss the real one. - Power factor / tan delta on windings and bushings

Trend it. One test is a snapshot. Trend is the movie. - thermal imaging infrared

Great for finding bad connections, cooling dead zones, bushing hot spots. Do it under load if you can.

DGA interpretation, practical steps

Here’s how I do it when I’m not being rushed.

- Look at trend. Not just “is it high.” Is it climbing fast?

- Check for acetylene. Any meaningful acetylene gets my attention immediately.

- Compare hydrogen, methane, ethylene mix. Thermal vs PD vs arcing.

- Check CO and CO2 if you’ve got them. Paper involvement.

- Correlate with loading, temps, events. Switching, lightning, through faults.

- Decide action. Monitor, de-load, plan outage, or trip it now.

- Don’t let people “email the vendor and wait two weeks.” Gas doesn’t wait.

Field nightmares

- CT polarity wrong. Differential trips on energization. Everybody blames the transformer.

- TTR done on wrong tap because someone didn’t read the dial.

- OLTC left in “manual” after checks. Then it never regulates. Then voltage complaints.

- Bushing test lead left connected. Yeah. That happens. Then you get fireworks. Then paperwork.

Reminds me of that winter job where we were doing TTR in a sleet storm, hands numb, meter screen fogging, and the PM says “can’t you just assume it’s fine, we need it energized.” Sure, man. Let’s assume 200 million dollars is fine.

10. Environmental/Regulatory/Grid Resilience Mess

This section always turns into a bar fight.

Oil, leaks, and disposal

Oil leaks aren’t “oops.” They’re EPA oil disposal reporting, soil remediation, angry landowners, and a crew stuck with absorbent pads in the rain.

- Mineral oil: common, cheaper, decent performance. Fire risk exists.

- Esters: better fire point, marketed as “green.” Still needs maintenance. Still can leak. Still costs more.

Old units and the fear word:

- PCB history. Most modern units are PCB-free oil. Old stuff, you test. You document. You don’t guess.

Fire risk

Oil + fault energy = bad time.

- Fire walls, deluge systems, nitrogen systems, containment basins.

- In urban substations, the public is right there. You don’t get to “wing it.”

Noise

Noise level regulations matter now. People build condos next to a substation and then complain the substation exists. So you add sound walls. Then airflow changes. Then temperature rises. Then losses rise. Then insulation life drops. Isn’t that neat?

Resilience

Everybody says grid reliability resilience like it’s a slogan you print on a mug. Real resilience is spare strategy, mobile transformers, standardized designs, and not running the fleet at 110% because “load growth surprised us.” Load growth never surprises anybody who’s paying attention.

And with renewable energy integration wind solar, you get:

- More switching

- More voltage swings

- Harmonics in some places

- Weird loading profiles

Transformers can handle a lot. They don’t handle neglect.

11. Standards You Live By or Die By

You’re gonna live in these whether you like it or not.

- IEC 60076

- IEEE C57

- ANSI standards

- UL certification for certain dry-type and building installs

Standards cover:

- Temperature rise limits

- Dielectric testing and BIL

- Loss evaluation

- Sound

- Short circuit withstand requirements

- Tap changer requirements

- Bushing specs and testing

Now the real talk. Standards are minimums and common language. They don’t guarantee you bought a good transformer. They guarantee you bought a transformer that can pass certain tests on a certain day.

I’ve seen units “meet spec” and still be dogs. Bad workmanship. Shipping damage. Poor drying. Sloppy internal leads. Stuff that doesn’t show up until it’s been heat-cycling for a year.

12. Real Applications Today – Grid to Data Centers

Transformers are everywhere, but 2026 has some special hotspots.

Traditional substations

- Big power transformer banks in substations feeding power distribution

- Autotransformers moving bulk power transmission

- Regulators and OLTC units keeping voltage inside limits

Renewables

- Wind farms: collector transformers, main substation transformers, and GSU generator step-up at the interconnect.

- Solar plants: inverters feeding MV, then step-up to HV. Lots of medium units. Lots of repetitive builds. Lots of chances to copy a mistake 40 times.

Data centers high demand

These loads are nasty in their own way.

- Fast growth. “We need 200 MW by next summer.” Sure you do.

- Redundancy expectations. N+1 everything.

- Harmonics depending on UPS and power electronics design.

- Tight voltage tolerance. They complain fast.

Industrial plants

Arc furnaces, mills, chemical plants.

- High cycling

- Harmonics

- Dust, vibration, heat

- Maintenance windows that are always too short

Offshore platforms

Salt, humidity, motion, limited access. Fun. Corrosion everywhere. You better care about insulation condition and sealing.

HVDC

HVDC converter transformers are their own religion.

- Harmonic currents

- DC bias risk

- Special insulation coordination, BIL coordination, and valve-side stresses

A converter transformer lead time right now? Don’t even ask if you’re in a hurry. You’ll cry into your coffee.

13. FAQ for Power Transformer

What’s the difference between a power transformer and an electrical transformer?

Electrical transformer” is the generic term. A power transformer is the big-grid class used in transmission and large substations, usually higher MVA, different design priorities.

How does voltage transformation happen?

Electromagnetic induction. AC in the primary winding builds changing flux in the iron core and that flux induces voltage in the secondary winding. Turns ratio sets the voltage ratio.

What causes transformer failure most often?

In my experience, insulation aging plus heat plus moisture, bushing failures, OLTC problems, and faults. Sometimes shipping damage that nobody catches until it’s too late.

What’s BIL and why should I care?

BIL Basic Impulse Level is the impulse withstand level for lightning and switching surges. If BIL coordination’s wrong, the transformer becomes the surge arrester. Briefly.

Is DGA really necessary?

Yeah. oil testing DGA Dissolved Gas Analysis acetylene hydrogen methane ethylene is one of the best early warning tools we’ve got. Ignoring DGA because “it’s still running” is how you buy a new transformer the hard way.

What tests should we run during commissioning?

Minimum, turns ratio test TTR, winding resistance, insulation resistance megger, power factor/tan delta, bushing tests, and if there’s any suspicion of mechanical damage then SFRA sweep frequency response analysis. Add partial discharge PD when appropriate.

What cooling type should we pick?

Depends on site, rating, footprint, fire risk, and load profile. ONAN is simpler. ONAF and OFAF add capacity and complexity. Dry-type and cast resin help indoor/fire concerns but come with their own limits.

14. The Brutal 2025-2026 Reality: Shortages, Prices, Future Fixes

Alright. Here’s the part where I stop pretending we’re in a normal market.

Supply chain shortages are still choking us. Everybody wants large power transformers LPTs yesterday. Manufacturers are booked out like it’s concert tickets.

Lead times? Don’t make me laugh.

- lead times 36-60 months

- 128-210 weeks

I’ve literally yelled at a manufacturer about a 210-week schedule that used to be 9 months-ish if you had your act together and your spec wasn’t insane. Now it’s “get in line, pal.”

And prices.

- price increases post-COVID 80%+ isn’t some rumor. I’ve watched budgets explode in real time.

Copper went up. Steel went up. Labor went up. Freight went up. Testing slots are booked. Everybody’s short on skilled people. Even the good shops are stretched thin.

Now pile on the aging fleet:

- aging fleet 38 years average gets tossed around and it tracks with what I see. Stuff installed when people smoked in control rooms is still carrying load. Some of it’s fine. Some of it’s one dissolved gas spike away from becoming scrap.

So what do you do? You can’t just “buy new ones.” Not fast.

Here’s what I tell stressed utility bosses and new guys.

1) Treat condition monitoring like it matters

DGA. Moisture. Bushings. OLTC. Thermal scans. Trend everything.

- Don’t just collect data. Act on it.

- Don’t ignore acetylene. Don’t hand-wave rising hydrogen.

- Don’t let someone talk you out of an outage when the data’s screaming.

2) Build a real spares plan

“Spare strategy” isn’t a PowerPoint.

- Identify critical substations.

- Match BIL, impedance, voltage, tap range, and cooling.

- If you can standardize designs, do it. It helps with interchangeability.

- Mobile transformer options. They’re not perfect, but they’re better than darkness.

3) Extend life intelligently

- oil filtration reclamation when it makes sense.

- Fix leaks before you lose dielectric margin and invite moisture.

- Upgrade breathers, add better sealing, consider nitrogen blankets where applicable.

- Overhaul OLTCs on schedule. Not when they explode.

4) Stop abusing units

I get it. Load’s growing. Data centers are popping up like weeds. But don’t run a transformer at emergency rating all summer and then act shocked when paper ages out.

- Watch hottest-spot.

- Watch cooling functionality.

- Verify fan/pump controls.

- Don’t bypass alarms because they’re “annoying.”

5) Specs and procurement, the painful part

Specs are getting longer and dumber in some places. Everybody adds a requirement after the last failure. Then the next bid comes in 40% higher and 18 months longer. You want to know why? Because you just made it custom again.

Better approach:

- Tighten what truly matters: BIL, impedance, losses, short-circuit strength, oil type, clear QA steps.

- Don’t sprinkle boutique requirements unless you can defend them.

- Require factory witness tests where it counts. Not for ego.

6) Grid resilience is operations too

You can do all the maintenance in the world and still get nailed by system events.

- Switching surge control

- Arresters sized right

- Grounding right

- Protection set right, with impedance reflection and transformer characteristics actually considered

And for the love of everything, stop treating a power transformer like it’s a breaker you can swap in a day. It’s not. It’s a long-lead, heavy, custom-ish piece of the power transmission machine.

Future fixes? Yeah, there’s talk.

- More domestic manufacturing.

- More standard designs.

- Utilities doing fleet programs instead of one-off panic buys.

- More ester adoption in certain locations because fire risk and permitting are brutal now.

- Better online monitoring.

But right now, in 2026, it’s triage sometimes. It’s prioritizing. It’s being honest about risk. It’s looking at a DGA report and saying “we’re not gonna gamble the whole station because we don’t wanna take a weekend outage.”

You know what’s wild? The physics hasn’t changed. Electromagnetic induction still does the same thing it did a hundred years ago. Primary winding, secondary winding, turns ratio, flux, core, heat, losses. Same story.

What changed is everything around it. Money. Lead times. Rules. Load. Weather. Expectations. And the fact that when a transformer dies now, you might not get a replacement before somebody retires.

Power Line Transformer: How It Works & Practical Guide 2026 Transformer on Wikipedia